454 Bullet test

Variations on a Nose

32 Rimfire Boot Pistol Restoration

Welcome to Glenn's Gun Room

Hi, just a little update on the project. Feb-2014

I guess it's been 10 years with no additional info, so here we go.

I bought 2 475 barrel blanks from Pac-Nor and turned them down to fit inside of the 12ga barrels that had been cut off to 24". I left 1" of the end of the barrels full diameter and then turned down the next 10" to a little under bore diameter.

My thinking was that I would shoot and see where the barrels were in relation to point of aim,

then file the end of the barrel down on one side and shim it over with some brass shims. In doing this I was

able to walk each barrel over to hit where the sights were aiming. When I got the first barrel walked into place, I soldered it in place.

Then went to work on the second barrel. I did all shooting from a standing bench at 50 yds.

For ammo, I initiallay loaded some 500gn solids loaded with RL15 at 2150fps, then compared that to 500gn cast bullets at 2150.

They both shot to the same point of aim, so all of the rest of the shooting was done with 500gn hard cast bullets.

I had Dan at MountainMolds.com cut me a 500gn .476" mould. The cast bullet loads would shoot into 1.5" at 50 yds,

I thought this was acceptable for open sights off of a standing bench. I worked on the second barrel and shimmed it over till the barrels

were shooting about 1.5" apart. I thought that I might as well get them to shoot exactly on top of each other and kept filing and shimming.

I went too far and had the barrels crossing. I thought that I would just weld that side of the barrel up a little and go back again,

working slower this time. Well, I got it too hot and blistered the inside of the barrel.

So it was back to square one on the second barrel. I orderd up another blank and did everything the same.

I got the two barrels within about 3" of each other and my time got eaten up with school, was working on a BS EE with CS minor, family and life.

The project sat unfinished in the gun cabinet for several years, we moved to Arkansas from Idaho 2 years ago and had a fire in our shop in September of 2013.

The gun was in a wodden gun cabinet and was ruined in the fire.

Some closing Points about the project.

At around 200 rounds of full pressure ammo being shot, the gun still locked up tight and would not close on a piece of paper.

At 300 rounds that action was starting to get a little wiggle in it.

I started with a light Belgian 12ga, what I should have started with was a heavy waterfowl gun.

Or went for a lower pressure round or something with a smaller body so bolt thrust would have been less.

Maybe a 45-120 or 50-110 would have been a better choice.

So that's it on this project. I'll clean it up some and use it for a wall hanger in the new gun room.

I have 2 Zabala 10 ga doubles that I was thinking of maybe doing a 600NE or 12gaFH, but they were in the same gun cabinet.

***************************************************************************

The first thought for this project was to build it on a 10ga double action,

but the gun is rather large and I thought it might be better to go with a more slender action.

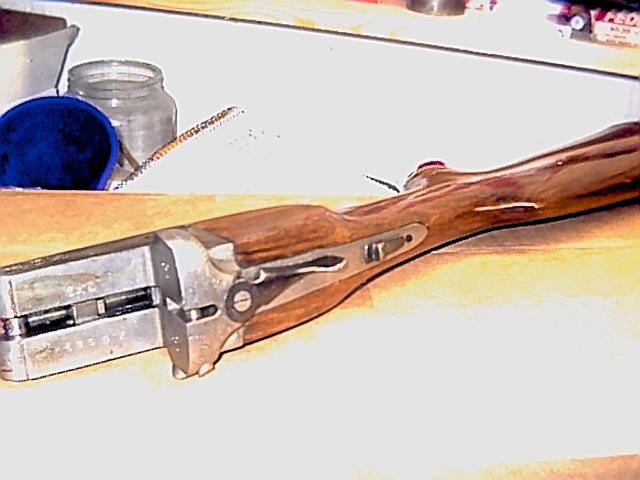

so I aquired a Blegian made 12ga. It has chopper lumps and a Greener cross bolt.

After fireing the first few box's of ammo, I noticed a crack in the stock. So it was repaired and reinforced with Brownell's acraglass and some machine screws. A steel recoil block was also added to help distribute the recoil.

I ordered some NECG express sights from Brownells and mounted them on the rib.

A rough outline of the project.

Useing Pac-Nor barrels.

The barrel blanks were ordered 34" long so I could cut to 24" and have some short barrels for a later pistol project.

Chamber Reamer from reamerrentals.com

Bell Brass

CH Tool & Die Reloading dies

I haven't found much reloading data yet. If you know of a source please email me.

idahobronco@aol.com

e-mail

I had a custom bullet mold made by

Mountain Molds

It is a 500grain gascheck design with 2 cavities in an XL mold.